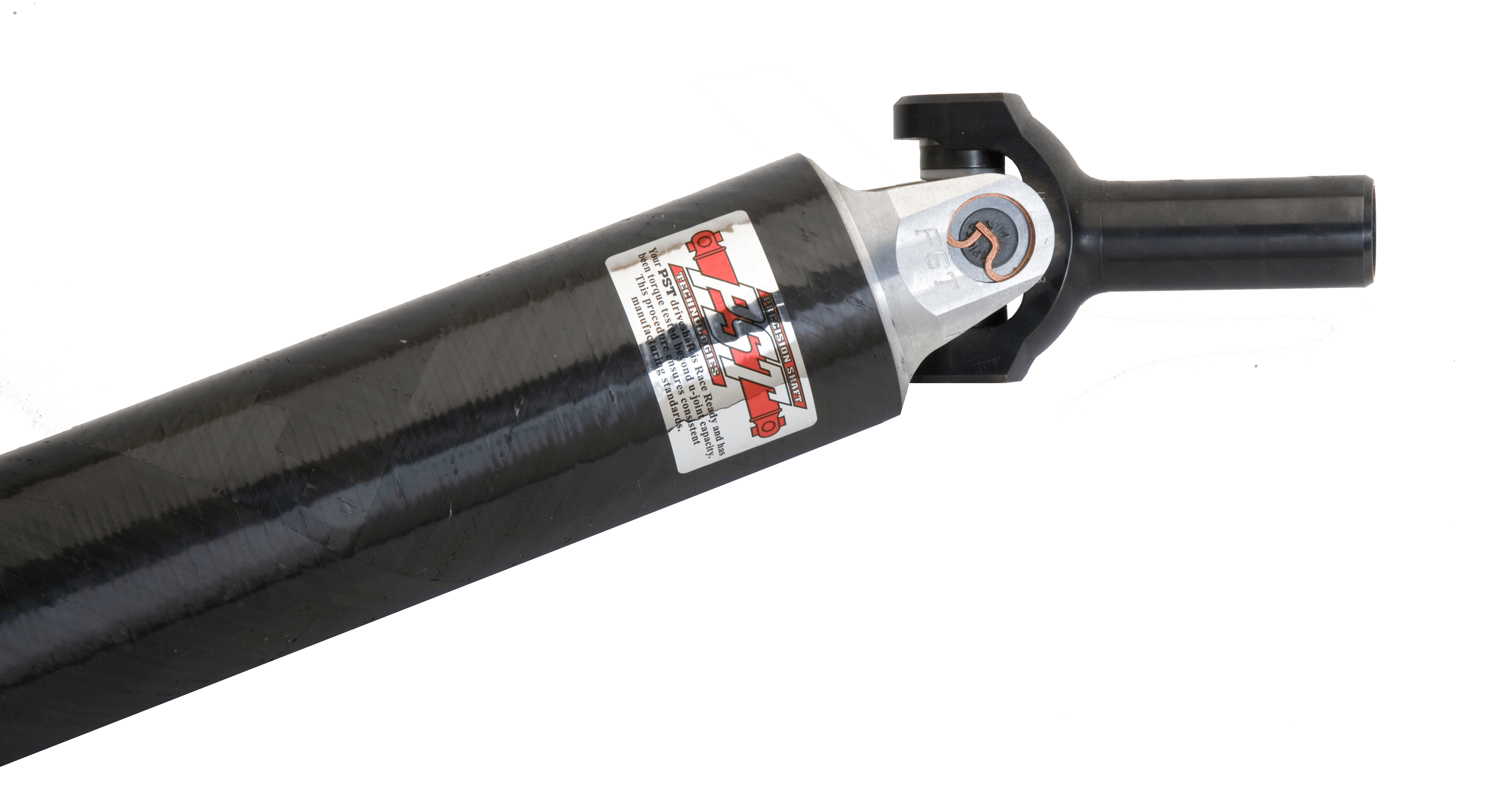

Carbon fiber driveshaft is a passion for many of you, whether you follow us on social media or keep up with what’s happening at the shop. Carbon Fiber Driveshaft is being reintroduced for the FRS/BRZ/GT86 platform.

Driveshafts are designed to be strong enough to take high torque loads and to save weight. To ensure that temperatures and pressure bonding are maintained, each driveshaft is baked in an autoclave mold. You can also get more information about carbon fibre driveshaft via https://pstds.com/driveshafts/carbon-fiber-driveshaft.

Image Source: Google

The driveshafts boast a 76% to 24% ratio of carbon to epoxy. This carbon to epoxy ratio allows for a 55% weight reduction compared to the OEM unit.

Our carbon fiber is made from a raw carbon fiber material, which is used by many automotive manufacturers, racing teams, as well as the military.

The same material is used by Nissan for the GT-R OEM driveshafts. It also finds its way onto missile bodies and high-pressure fuel tanks.

Each end is made from 7075-T6 aluminum with high-quality u-joints featuring low stiction. These ends can be cold-forged or heat-treated and have an antioxidation treatment.

The driveshafts were tested to a torque of 3600+ ft.lbs or 5000nm. The driveshaft was also fatigue tested at 2000nm per cycle for 100,000 cycles. The driveshafts are balanced at 8,000 to 10,000 RPM, ensuring that there is no vibration.